Bigge Crushing and Conveying

- Client: Fortescue

- Location: Pilbara, Western Australia

- Date: 2020 - 2021

View project

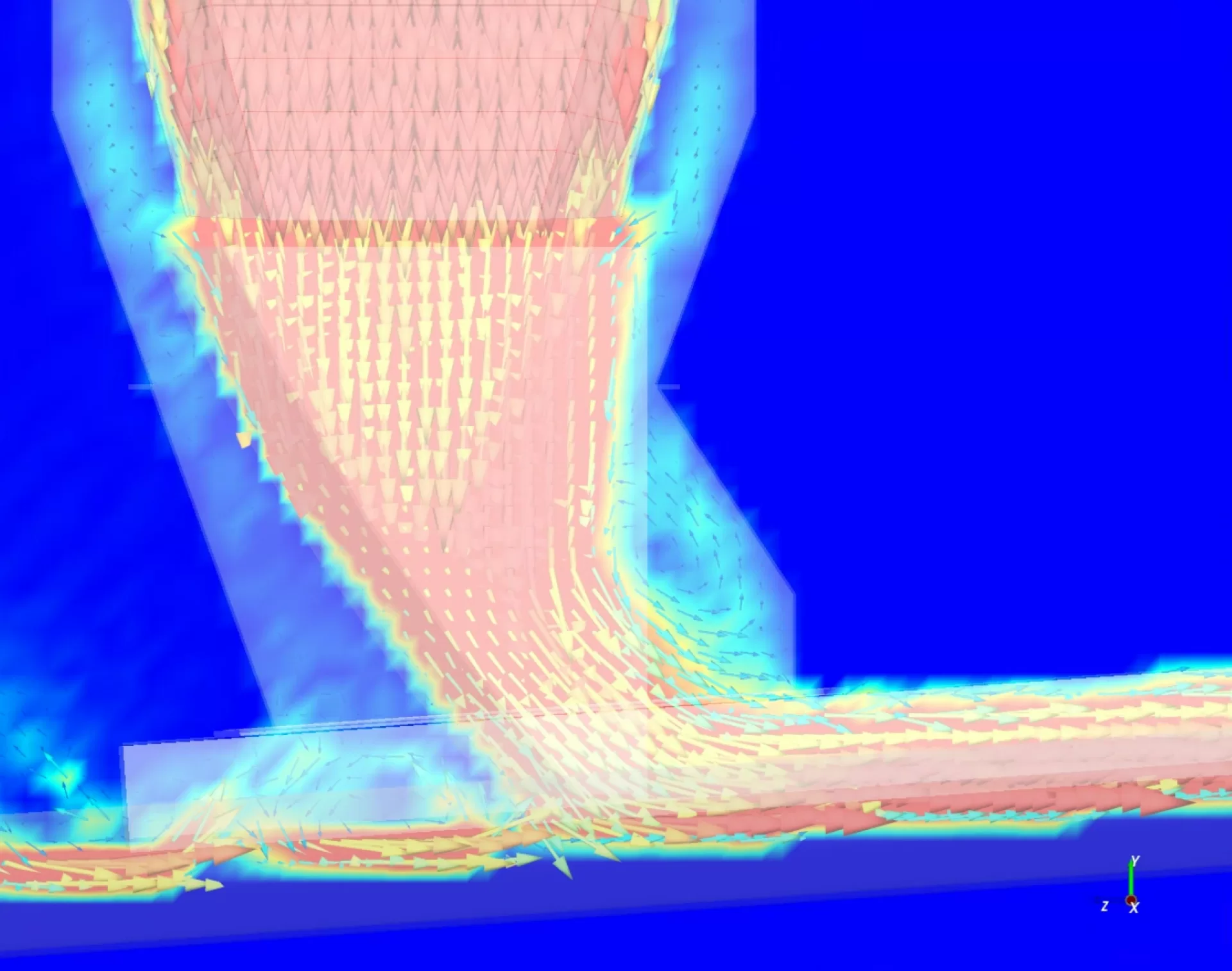

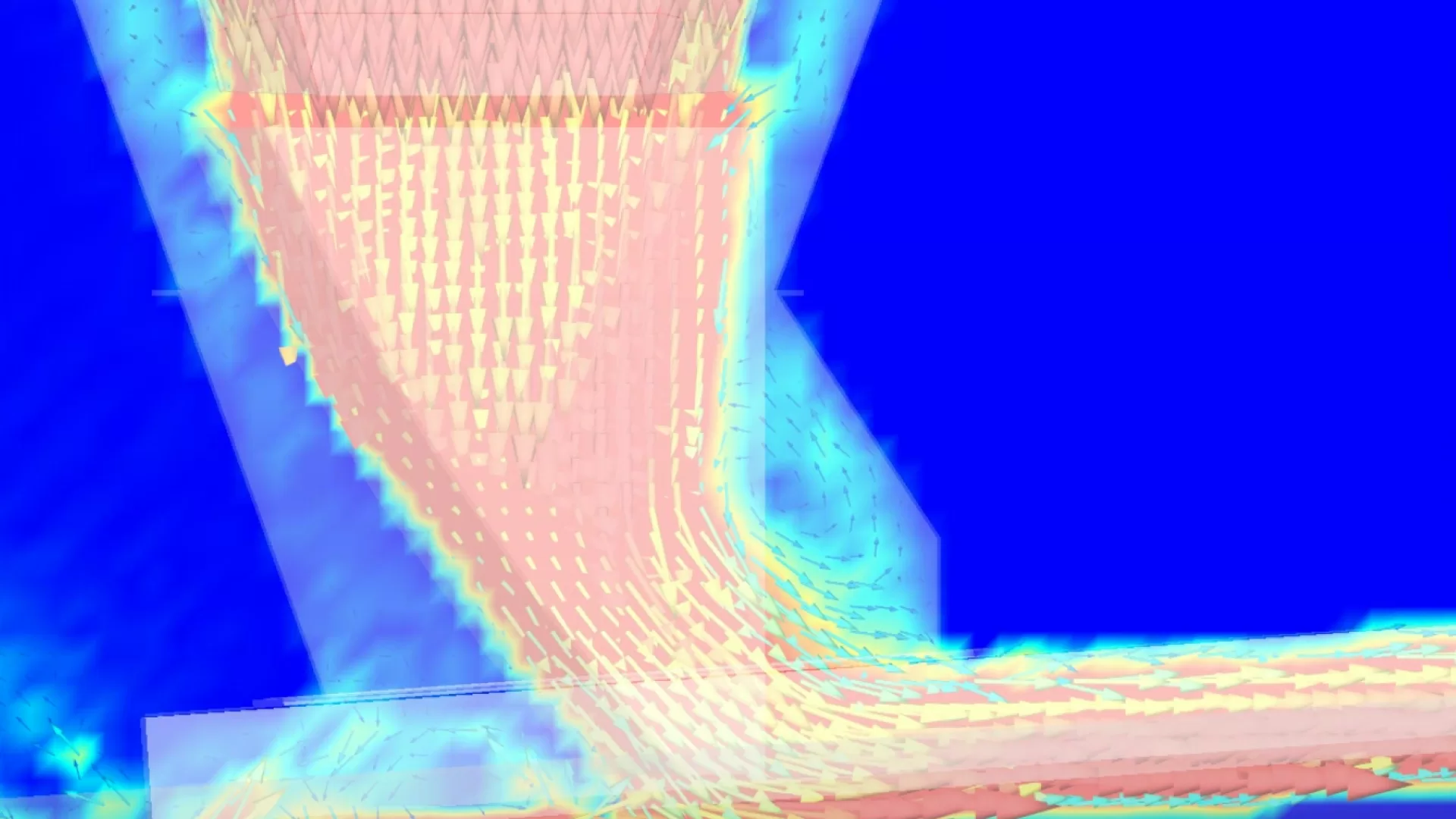

A client operating an iron ore processing facility was experiencing significant dust generation from an ultra-fines iron ore transfer chute. The excessive dust not only posed environmental and health risks but also increased operational costs due to the need for secondary dust control measures such as conveyor covers, active dust extraction, sealing, and water addition. Seeking a more effective and sustainable solution, the client engaged EMtek to redesign the chute using advanced simulation techniques.

To accurately diagnose and address the issue, EMtek leveraged a coupled Lattice Boltzmann Method (LBM) and Discrete Element Method (DEM) simulation. This powerful computational approach enabled engineers to:

The redesigned transfer chute was successfully commissioned on-site and delivered significant reductions in dust emissions. By controlling airflow within the chute, the need for additional dust suppression measures such as water addition and active dust extraction was greatly reduced.

This case highlights how EMtek’s expertise in advanced simulation and materials handling engineering can deliver practical, high-impact solutions for challenging industrial environments.